Corrugated flutes are the backbone of a corrugated box. They are the wavy, arch-shaped pieces of paper that you see when you look at the edge of a corrugated box. They are sandwiched between two flat pieces of paper, known as linerboards. The strength, durability and other features of the box depends on these flutes. While designing a corrugated box, you need proper guidance regarding the selection of suitable corrugated flutes and that comes from a corrugated flute chart. It shows different types of corrugated flutes. Each type has a unique size and number of flutes per foot. The chart helps you understand these differences. For example, A-Flute is the largest type and offers excellent cushioning. E-Flute is thinner and provides a high-quality print surface.

Moreover, you must have heard that custom boxes keep the product safe from temperature. Do you know how? It is the corrugated flutes that allow air circulation which ultimately work as an insulator to control the temperature changes.

By using the chart, you can pick the right flute type for your packaging needs. Whether you need to ship a fragile item or create an attractive retail display, the corrugated flute chart guides you to choose the best.

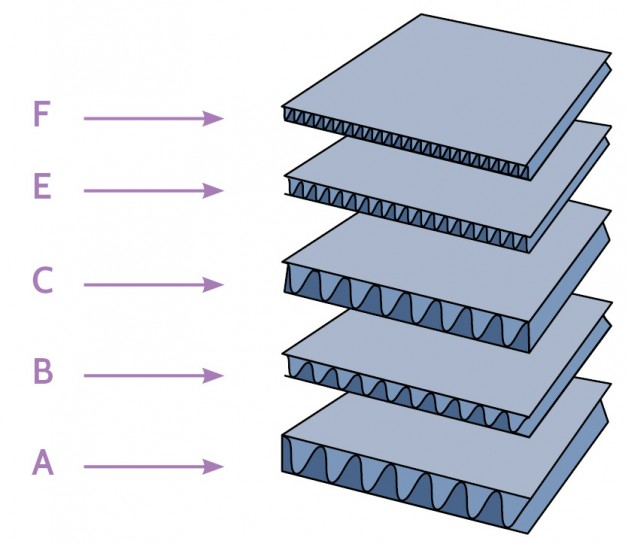

Types of Corrugated Flutes

There are several types of corrugated flutes, each with its own characteristics and uses. Here are the most common ones:

A-Flute

This is the original corrugated flute design and is the largest type. It has about 33 flutes per foot. A-Flute offers excellent cushioning and stacking properties for fragile and delicate items.

B-Flute

B-Flute is smaller than A-Flute, with about 47 flutes per foot. It provides good puncture resistance and is commonly used for canned goods and displays.

C-Flute

C-Flute is the most commonly used flute size, with about 39 flutes per foot. It offers good cushioning, stacking and printing properties. It’s often used for shipping boxes and retail packaging.

E-Flute

E-Flute has about 90 flutes per foot and is thinner than B-Flute. It offers excellent crush resistance and printing properties. It’s often used for pizza boxes and mailers.

F-Flute

F-Flute is the smallest flute size with about 128 flutes per foot. It provides excellent crush resistance and a high-quality print surface. It’s often used for retail packaging and small consumer goods.

How to choose corrugated Flute?

There are two factors that you need to consider while selecting a corrugated flute.

Board Type

The type of board you choose affects the strength and flexibility of the box. For example, single wall boards are lighter and more flexible, but double wall boards are stronger and more rigid. So, if you need a box for heavy items, you might choose a double wall board and a larger flute like A or B. For lighter items, a single wall board with a smaller flute like E or F might be enough.

Box Style

You can also consider the following box styles to store and display your products.

1. Archive Box: These boxes are simple and classy. They have a layer of corrugated flute that you can stack and put together easily. They are perfect for packing things like books and artwork.

2. Mailer Box: These boxes are strong, stylish, and have dust flaps. They are great for online businesses and subscription services because they can keep products safe during transit.

3. Shipping Box: These boxes use a B-flute corrugated board. They have a classic, sleek look and offer good protection. You can use them to ship just about anything.

Printing Techniques

Corrugated boxes are not always in simple brown shape. You can make your corrugated boxes look stylish and attractive to enhance the perceived value of the product inside. You can use the following printing technique for corrugated flutes.

- Flexographic Printing

- Lithographic Printing

- Digital Printing

In short, if you belong to a packaging industry, it is important for you to know about the corrugated flute chart. It helps you to select the suitable type and size of corrugated flute for your desired box. Whether you want to design a mailer box, a product box, a shipping box or a packaging solution for your retail products, using the right numbers of corrugated flutes is very important. You can ensure the durability, aesthetic apparel and printing quality through corrugated flues.